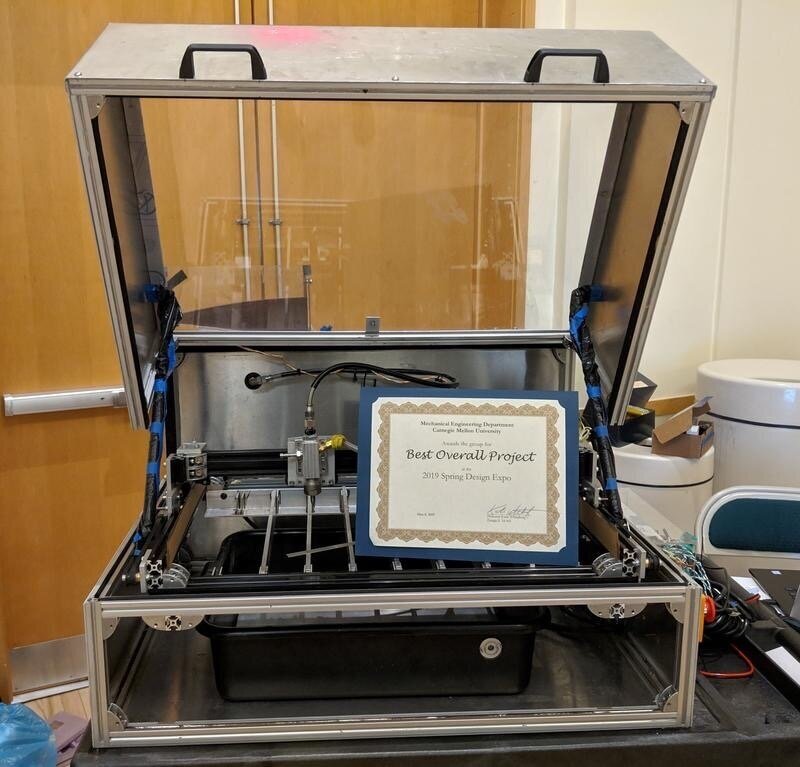

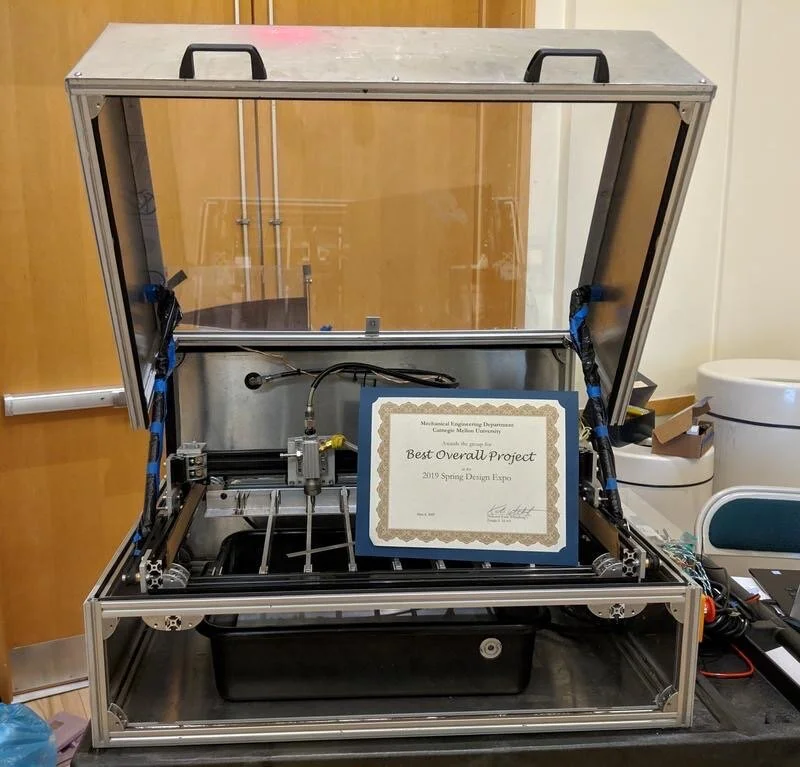

The team at the design expo with the waterjet cutter

Desktop Waterjet

Spring semester of my senior year at Carnegie Mellon, I participated in a successful Design Capstone project. My team designed and created a desktop waterjet cutter. We identified a potential gap in the market: there are currently no options for DIYers, hobby shops, or student teams to own and operate a waterjet. With industrial products being in the $100000 range, we sought to create a capable option for less than $1000.

Major features of our final design included its ‘plug-and-play’ capability with any off the shelf pressure washer, simple CNC control with a laptop interface, and attention to user safety.

Significant testing had to be done to optimize the flow of the abrasive particles, and their mixing with the high pressure water stream. After tweaking the design we were able to successfully cut aluminum sheet metal, along with thick foams. We also demonstrated accuracy of our gantry and CNC control systems by performing repeat-ability tests.

At the Mechanical Engineering Spring Design Expo, our team won ‘Best Overall Project’